Multi-bag filter, stainless steel multi-bag filter,Multi-bag filter, quick-opening bag filter, cartridge filter bag filter, swing-arm multi-bag quick-opening filter (rocker-arm quick-opening bag filter) circulating water filter, etc. are an early filtration equipment. The inner part of the filter is supported by a metal mesh basket. The liquid flows in from the inlet and flows out from the outlet after the filter bag filtration. The impurities are blocked in the filter bag until the differential pressure is reached.Continue to use after replacing the filter bag. Filtering accuracy is 1-200 micron for selection, easy operation and low cost.

|  |

|  |

Application field of multi-bag filter

Water treatment: (1) removing sand particles from seawater; (2) ion exchange resin recovery; (3) system purification in cooling device; (4) cooling water purification in power plant; (5) removing sludge from mineral water; (6) filtering chemicals used for water treatment; (7) filtering of urban water supply; (8) removing calcium crystallization; (9) filtering of oilfield water injection and completion fluid;

Food and beverages: (1) filtration of stabilizers in beer; (2) purification of wine, whisky and beer; (3) removal of impurities from edible oils; (4) removal of carbon inks from cellulose; (5) filtration of industrial sugar paddles; (6) filtration of animal and plant extracts; (7) filtration of edible vinegar and sauce; (8) filtration of coatings for tin cans; (9) alkaline liquor for bottle washingFiltration;

Chemicals: (1) filtration of catalysts; (2) filtration of acid and alkali solutions; (3) removal of carbon inks and filter aids; (4) removal of emulsions and suspensions;

Binder: (1) removing gel from acrylic adhesive; (2) removing resin and crystals; (3) filtering of varnish and top-coat; (4) filtering of pre-treatment phosphating solution and water; (5) filtering of electrophoretic paint and pre-treatment solution; (6) filtering of spray water;

Textile industry: (1) filtration of textile dyes; (2) filtration of NaHSO4 solution, water and spinning solution in acrylic fiber production;

Design features of bag filter (machine)

Bag Filter Confidential Seal: All bag filters (machine) cartridges are compatible with filter bags with patented sealing rings and the cartridge seals are generated by a combination of port structures.When the filter bag is loaded, the sealing ring will be stuck in the snap ring at the end of the filter cartridge, which not only completely prevents liquid leakage, but also effectively prevents the possibility of the filter bag falling into the net basket under the working pressure.The smooth driving and guiding structure of the sealing ring makes installation and removal of the filter bag easier and avoids splashing of the material.

Self-pressure sealing ring, which eliminates the possibility of impurity bypass and makes bag replacement easier. During the filtration process, self-pressure sealing ring turns over under the action of pressure as the pressure difference increases.

Tightly adhere to the top cover and basket, making it a stable one, which prevents the upstream liquid from leaking into the downstream filtered liquid and ensures the quality of filtration.

Patented ring opening is used for the filter bag, which is tightly adhered to the filter without loosening. Multiple seals provide better sealing effect.

Standard side-in and bottom-out multi-bag filters for large flow filtration.

{From 2 bags to 24 bags, complete specifications, diameter of inlet and outlet flange DN80~DN400", maximum flow of single machine 90~1, 080m3/h.

Dual exhaust and discharge openings are designed to make the filter convenient and safe.

The multi-bag filter is made of different materials such as carbon steel CS, 304 stainless steel and 316L stainless steel; suitable for handling various acid-base liquids, solvents and neutral liquids; also suitable for comparison.

When the filter bag is replaced after a long time.

_size filter bags or screens are selected; bag replacement is very convenient.

Smooth fluid piping design, small pressure loss, more energy-saving; excellent sealing design, in conjunction with W-type patented ring, overcome the side leakage stubborn disease of traditional filters.Quick-open design, easy maintenance.

Shanghai Double-start Fluid Separation Technology Multi-bag Standard Filter

Detailed technical parameters are as follows:

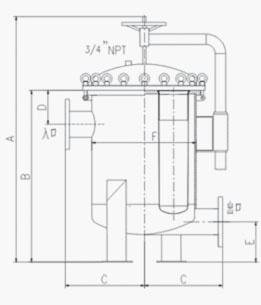

Physical drawings Dimensional schematic

Dimensional parameters

Model | Number of filter bags | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | F (mm) | Max. flow rate (m3/h) | Connection mode of import and export |

HECB90 | 2 | 1330 | 930 | 300 | 150 | 150 | 400 | 90 | 3"-4"flange |

HECB135 | 3 | 1350 | 950 | 350 | 160 | 160 | 500 | 135 | 3"-4"flange |

HECB180 | 4 | 1420 | 965 | 380 | 170 | 170 | 550 | 180 | 3"-6"flange |

HECB225 | 5 | 1450 | 985 | 400 | 190 | 190 | 600 | 225 | 3"-6"flange |

HECB280 | 6 | 1500 | 1000 | 430 | 190 | 190 | 650 | 280 | 3"-6"flange |

HECB360 | 8 | 1550 | 1120 | 480 | 230 | 220 | 750 | 360 | 4"-8"flange |

HECB450 | 10 | 1675 | 1160 | 555 | 260 | 250 | 900 | 450 | 6"-8"flange |

HECB550 | 12 | 1690 | 1175 | 580 | 260 | 250 | 950 | 540 | 6"-10"flange |

HECB650 | 14 | 1720 | 1090 | 610 | 260 | 250 | 1000 | 630 | 8"-10"flange |

HECB750 | 16 | 1750 | 1100 | 635 | 300 | 280 | 1050 | 720 | 8"-12"flange |

HECB800 | 18 | 1780 | 1130 | 685 | 300 | 280 | 1150 | 810 | 10"-14"flange |

HECB900 | 20 | 1800 | 1145 | 710 | 300 | 280 | 1200 | 900 | 10"-16"flange |

HECB1000 | 22 | 1820 | 1160 | 735 | 300 | 280 | 1250 | 990 | 12"-18"flange |

HECB1100 | 24 | 1850 | 1175 | 760 | 320 | 300 | 1300 | 1080 | 14"-18"flange |

Technical data sheet for economical multi-bag filter:

Model | Number of filter bags | Type of filter bags | Surface area of filter cartridge(m2) | Dimensions of inlet and outlet (nominal) | Max. flow rate (t/h) |

HECB-5 | 1 | 3# | 0.046 | 1" | 5.75 |

HECB-10 | 1 | 4# | 0.092 | 1" | 10.35 |

HECB-20 | 1 | 1# | 0.184 | 2" | 20.70 |

HECB-45 | 1 | 2# | 0.405 | 2" | 45.50 |

HECB-90 | 2 | 2# | 0.81 | 3-4" | 91.00 |

HECB-135 | 3 | 2# | 1.215 | 3-6 | 136.5 |

HECB-180 | 4 | 2# | 1.62 | 4-6 | 182 |

HECB-225 | 5 | 2# | 2.025 | 4-8 | 227.5 |

HECB-270 | 6 | 2# | 2.43 | 4-8 | 273 |

HECB-315 | 7 | 2# | 2.835 | 6-8 | 318.5 |

HECB-360 | 8 | 2# | 3.24 | 6-8 | 364 |

HECB-405 | 9 | 2# | 3.645 | 6-8 | 409.5 |

HECB-450 | 10 | 2# | 4.05 | 6-8 | 455 |

HECB-540 | 12 | 2# | 4.86 | 8-10 | 546 |

HECB-630 | 14 | 2# | 5.67 | 10-12 | 637 |

HECB-720 | 16 | 2# | 6.48 | 10-12 | 728 |

HECB-810 | 18 | 2# | 7.29 | 10-14 | 819 |

HECB-900 | 20 | 2# | 8.10 | 10-14 | 910 |

HECB-990 | 22 | 2# | 8.91 | 10-14 | 1000 |

Copyright © 2018 Shanghai Shuangqi fluid separation technology Co., Ltd All Rights Reserved.

Email:121586348@qq.com Powerd by:

PEERHI